The diversity of bead nozzles: A look at the precision in adhesive application

The world of adhesive application contains a wealth of technology and tools; all aimed at applying adhesive precisely and efficiently exactly where it is needed. A crucial component of this process is the nozzle. Cone nozzle, tube nozzle, nozzle cone (with capillary), round tube nozzle, flat tube nozzle or the bead nozzle – the selection is wide and each model has its specific application and properties.

The structure of a nozzle

Essentially, in the case of bead nozzles, it all boils down to forming a bead of adhesive. But the reality is much more complex than the mere principal. Choosing the correct nozzle depends on a variety of factors, including the specific application, the hot-melt adhesive used, and the type of application desired.

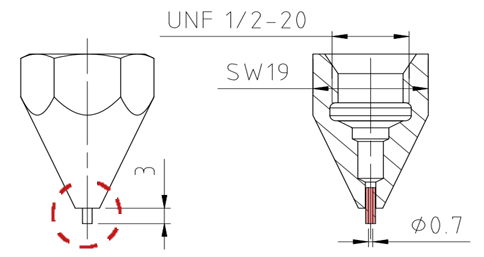

The design of a nozzle is usually conical to enable precise dosage of the adhesive. The inner diameter of the nozzle largely determines the amount of hot-melt adhesive that is discharged. The simple rule applies: a small diameter means less adhesive, while a larger diameter releases more adhesive. A diameter of 3.0 mm is considered large.

Diameters under 0.5 mm are particularly critical, as the viscosity of the hot-melt adhesive used plays a role here. High pressure is often required to ensure a clean application. In order to avoid blockages, upstream filters are used for small diameters.

The tear-off behaviour

In order to improve the tear-off behaviour of the adhesive thread, some nozzle models contain a capillary insert. The thinner the wall thickness of this capillary, the better the thread tear-off. In addition, some models are equipped with a protective collar to protect the capillary and nozzle tip from damage.

The choice of material for the nozzles is crucial. Steel, stainless steel, aluminium and brass are used here. Due to its good thermal conductivity, brass offers optimal temperature control for adhesive applications, but is comparatively susceptible to wear. Stainless steel, on the other hand, is harder and more resistant, but with lower thermal conductivity.

Regular replacement

It is important to remember that nozzles are wearing parts and must be cleaned regularly and replaced if necessary to ensure precise adhesive application. Wear can occur both by contact with materials, as well as “washing out” by the hot-melt adhesive.

- Blocked hot-melt adhesive granules – causes, effects and solutions - 11. März 2025

- Temperature sensors: The invisible heroes in melting devices - 21. Januar 2025

- Fracture patterns when bonding: What they say about the connection - 14. Januar 2025