Temperature sensors: The invisible heroes in melting devices

Temperature sensors are indispensable components in melting devices. They ensure that hot-melt adhesives always have the right temperature for optimal processing. But not all temperature sensors are the same – there are different types with special properties and functions.

Why are temperature sensors so important?

In melting devices, precise temperature control is crucial. Too cold – and the adhesive does not flow properly. Too hot – and the quality of the adhesive suffers. Temperature sensors continuously measure the temperature and pass this information on to the system’s control system. This can then adjust accordingly to create perfect conditions.

The four main types of temperature sensors

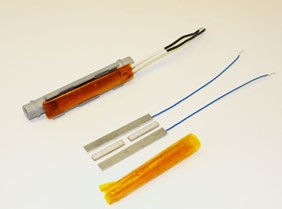

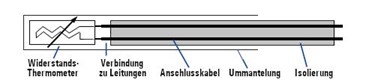

PT100 – The precise one

The PT100 is the workhorse among temperature sensors. It is based on platinum, which changes its resistance when the temperature changes. This makes it particularly precise and stable – perfect for applications where absolute precision is important.

Ni120 – The fast one

This nickel resistance thermometer is similar to the PT100, but has a somewhat simpler design. It is a cost-effective alternative and impresses with its fast response time. This is ideal if you want to combine accuracy with a good price-performance ratio.

NTC – The sensitive one

NTC (Negative Temperature Coefficient) means that the resistance of the sensor decreases as the temperature increases. NTC sensors react extremely quickly to temperature changes, are highly sensitive and are particularly suitable when fast response times are required.

- FeCuNi – The robust one

FeCuNi (iron-copper-nickel) sensors are the all-rounders for demanding environments. They are robust and particularly good at precisely measuring temperature fluctuations. When things get hot, they are the right choice.

What about hot glue guns?

Mechanical hot glue guns rely on a different technology: PTC (Positive Temperature Coefficient) temperature sensors. These are particularly clever, because their resistance increases with the temperature. This means that they virtually regulate themselves and ensure that the temperature of the heating element remains constant – perfect for compact, cost-effective devices.

The bottom line 💡

Each temperature sensor has its strengths and each system manufacturer has its favorite. But they all have one thing in common: they ensure that hot-melt adhesives are always at the perfect temperature.

The next adhesive bond you make is therefore not only the result of a good adhesive, but also the performance of an invisible hero – the temperature sensor.

- Our YouTube channel – knowledge to view - 6. Mai 2025

- Efficient adhesive supply with the granulate conveyor: How to optimise your production: - 15. April 2025

- Blocked hot-melt adhesive granules – causes, effects and solutions - 11. März 2025