Reactive adhesives

The combination of the advantages of two adhesive worlds: Polyurethane hot-melt adhesives combine the advantages of physically setting hot-melt adhesives with those of reactive one/two component adhesives. High processing speeds and high adhesive strength combined in one product allow high-strength, constructive bonding. They are always used when exceptionally high temperature resistance is to be achieved while, at the same time, having good flexibility at low temperatures and resistance to a wide range of chemicals. The bonds have a high resistance to aging in products with a long service life. Standard PUR hot melts with an MDI content >0.1% are subject to labelling.

You can process the adhesive manually in small cartridges or in automated processes with drums of up to 200 kg. Close advice and support from our laboratory and technical team helps with choice of the right adhesive, substrate and process design. We would be glad to assist you if you have any questions regarding occupational safety when dealing with reactive hot-melt adhesives.

Your advantages when using reactive PUR / POR products:

![]() High cohesion enables constructive bonds

High cohesion enables constructive bonds

![]() High temperature resistance in the cold as well as in the heat enable, for example, use in the automotive industry

High temperature resistance in the cold as well as in the heat enable, for example, use in the automotive industry

![]() Resistance to plasticizers, oils and solvents enables the bonding of soft PVC and demanding filter applications

Resistance to plasticizers, oils and solvents enables the bonding of soft PVC and demanding filter applications

![]() High level of ageing stability of the bond

High level of ageing stability of the bond

![]() PUR have a very wide adhesion spectrum to many plastics, for instance ABS

PUR have a very wide adhesion spectrum to many plastics, for instance ABS

![]() POR offer a very good adhesion spectrum to low-energy surfaces, for example PP

POR offer a very good adhesion spectrum to low-energy surfaces, for example PP

Our product range

Further adhesives on request.

E3848 ME, micro-emission, exempt from labelling

Very good initial strength, very good adhesion on various substrates, and is suitable, for example, for assembly bonds in car interiors. Due to the free MDI content < 0.1% the product is exempt from labelling.

- MDI < 0.1 % = label-free

- Good sprayability

- Good initial strength

E0931.3

Structural bonds with high demands on strength and reaction to changes in temperature

- Moisture curing

- Long open time

- Good solvent resistance

- High cohesion

E1075.2

Structural bonds with high demands on strength and reaction to changes in temperature

- Fast handling strength

- Average open time

- Moisture curing

- Good solvent resistance

B1452.1

For bonding low-energy surfaces with high demands on the cohesive behaviour.

- Solvent-free

- High heat resistance

- • Good flexibility at low temperatures

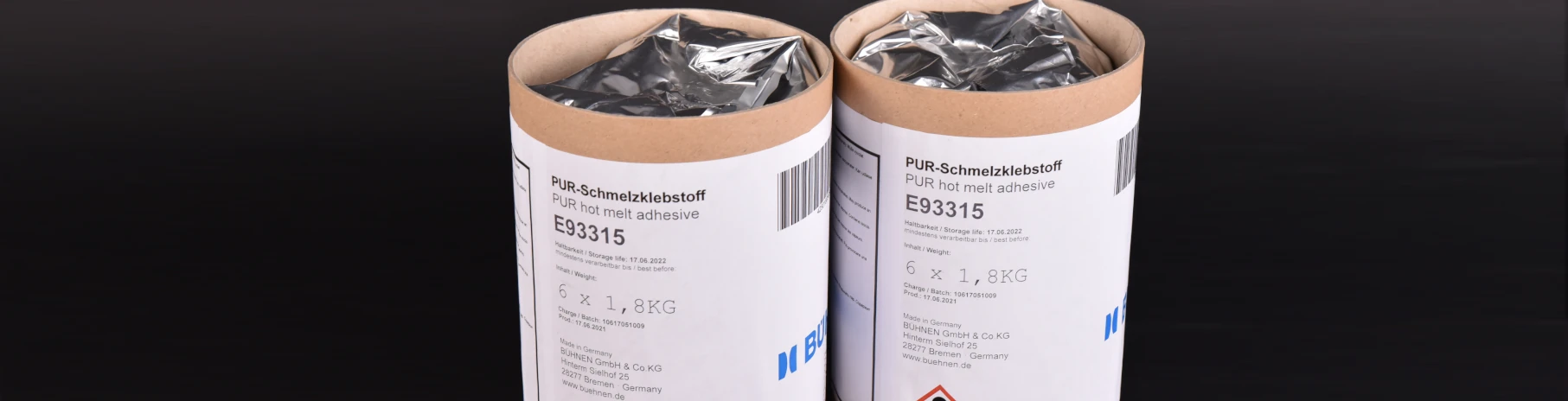

E3315

Particularly suitable for surface lamination and light assembly bonds. Due to the reduced MDI content < 1%, the H351 labelling is no longer required.

- Low MDI < 1 %

- Good sprayability

- FDA guidelines 175.105

- Very long open time

E3379

Particularly suitable for surface lamination and light assembly bonds.

- Excellent solvent resistance

- Very soft glue line

- Long open time

- Good sprayability

E2456UVM

For assembly and constructional bonds that are exposed to high temperatures. Available in black and white.

- Low processing viscosity

- Moisture curing

- UV marked

- Fast cohesion build up

- Good solvent resistance