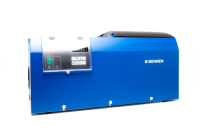

HB 5010 bead, gear pump

Advantages and equipment features

The HB 5010 is a hot melt adhesive tank system with gear pump, especially for manual applications.

- 4.5 litre capacity

- Robust and easy-to-clean plastic housing

- Fast heating-up in less than 30 minutes

- Intuitive user guidance

Specifications

Application Areas

Description

The HB 5010 is a hot melt adhesive tank system with gear pump, especially for manual applications. Together with the hand gun HB 910, the tank system is ideally suited for all bead or spray bonding.

The construction of the simple menu navigation of the control unit is so user-friendly that the intuitive operation of the device is possible even for untrained personnel.

The extremely resilient plastic housing has a dirt-resistant paint finish. The modular structure of the system increases the ease of maintenance and ensures good accessibility of the parts when servicing. A filter change is possible without additional disassembly.

A conveyor system with gear pump ensures a constant volume per unit of time. The simple design of the pump makes it robust and inexpensive. The construction of the pump also enables the processing of polyamides up to 210°C.

Up to 2 hot melt hoses can be connected. In combination with application heads, automation of simple tasks is possible.

Thus, all major hot melt adhesives (EVA, PA, PO and PSA) can be processed without problem in bead, dot and/or spray application.

Advantages and equipment features

- Intuitive user guidance

- Integrated weekly clock

- Robust and easy-to-clean plastic housing

- Connection of up to two hoses

- coated aluminum tank

- 4.5 litre capacity

- Fast heating-up in less than 30 minutes

- High melting capacity 4.5 kg/h

- Service-friendly, modular structure

- Integrated filter

- Maximum cleaning comfort

EVA Hotmelt A0158.1

EVA Hotmelt A0158.1 Hand gun HB 910 Bead

Hand gun HB 910 Bead Hot Melt Hoses for Application Heads - Bead

Hot Melt Hoses for Application Heads - Bead