Ethylene vinyl acetate (EVA) is a base polymer commonly used in standard adhesives. It is the basis of hot melt adhesives used in floristry, handcraft and the packaging industry, amongst other sectors.

Ethylene vinyl acetate (EVA) is a base polymer commonly used in standard adhesives. It is the basis of hot melt adhesives used in floristry, handcraft and the packaging industry, amongst other sectors.

EVA based hot melts are 100% solid and transparent in their basic form. They are multicomponent systems in which the properties can be adjusted by skilfully combining various polymers and additives. EVA hot melt adhesives contain about 33% polymer. These polymers have good compatibility with the additives. Additives can include resin, wax, oil, fillers and tackifiers with which the flowability, cure time, setting time, softening point or colour are controlled. The adhesive acquires its characteristic properties from the recipe.

EVA-based hot-adhesives are distinguished by their relatively short cure times and setting times, along with other characteristics. This type of hot melt adhesive is frequently processed in the form of sticks using hot glue guns. One of the benefits of EVA hot melt adhesives is that under Regulation (EC) No 1272/2008, ethylene-vinyl acetate is classified as non-hazardous and is not subject to labelling requirements under the EC Directive.

EVA-based hot-adhesives are distinguished by their relatively short cure times and setting times, along with other characteristics. This type of hot melt adhesive is frequently processed in the form of sticks using hot glue guns. One of the benefits of EVA hot melt adhesives is that under Regulation (EC) No 1272/2008, ethylene-vinyl acetate is classified as non-hazardous and is not subject to labelling requirements under the EC Directive.

The processing temperature of this type of adhesive is usually 170°-200° C. Its almost inert structure gives good thermal stability. This means that EVA can be relied on to maintain its cohesive strength and bond strength properties at these temperatures.

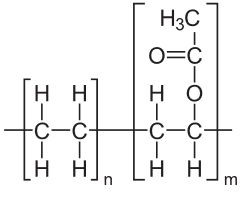

However, an excessive heat load can damage the weak point in the polymer chain, destroying the O = C double bond. Above 210°C, this part breaks away, resulting in acetic acid that creates nuisance odours. If EVA adhesives are to be processed at these temperatures, or higher, it is advisable to set up an extraction system in the workplace. It should be noted that at these high temperatures, the properties of the adhesive are changed. If you are planning to use this adhesive in such a way, it is essential to consult your local BÜHNEN contact.

It is the balanced adhesion/cohesion ratio and good price/performance ratio make this type of adhesive so successful. That is why many of the hot glue sticks available in hardware stores and used in the hobby sector are based on EVA.

Benefits of EVA adhesives

- Can be used universally

- Balanced adhesion/cohesion ratio

- Good price/performance ratio

- Safe and does not require labelling

- Good thermal stability up to 200°C

Limits of EVA adhesives

- Poor adhesion to low-energy non-polar surfaces (e.g. PP, PE, PS plastics)

- Tends to be unsuitable when long cure periods are required