The boom in online trade continues unabated. Connected to the shopping experience is the shipment of the ordered goods. Particularly in the shipping of textiles, foil bags are an alternative to cardboard boxes. All bags are fitted with one or more practical self-adhesive strips.

The boom in online trade continues unabated. Connected to the shopping experience is the shipment of the ordered goods. Particularly in the shipping of textiles, foil bags are an alternative to cardboard boxes. All bags are fitted with one or more practical self-adhesive strips.

Thousands of bags had been securely closed during our history. But all of a sudden, unexplainable faulty closures occurred; A case for Amelie “Watson” Greif and Andreas “Sherlock” Ditze.

“On a dull grey April morning in Bremen, the telephone rang in the Project Manager’s office. Sherlock Ditze took the call. On the line was the BÜHNEN informant from the field service. Excited, he started his extensive report…..”

In this or a similar manner, our history could be re-told. In the case of the mailing bag, Andreas Ditze and his colleague Amelie Greif from the laboratory had to be as meticulous as detectives in their search for the solution.

Thousands of mailing bags could be made by the customer without any problems. These mailing bags are used as shipping packaging for clothing ordered on the Internet. In our case, there are two different versions: Bag A had been in use the longest and there were no problems with the gluing. With Bag B, which came into the programme later, the bonding was found to be unsafe.

“Watson Greif, we have several suspects on our list. We will have to take a closer look at each one of them. Open up the lab!” Sherlock Ditze picked up his instrument bag and made his way to the applications laboratory.”

Both bags are made of the plastic polyethylene. Additives are often added to PE film: These additives are used to determine the properties of the film. The film thickness, weldability, stiffness or optical appearance can be designed. The exact mixing additives, such as anti-statics, lubricants or chalk are not always known, as the film is often purchased.

Suspect No. 1: Recyclate

In the case of the old bags, PE recyclates were used. Recyclates are often the first suspects when a bond cannot be completed successfully, because their exact ingredients/mixing ratios are often unknown or can even be changed within the production batches. In this case, the recyclates can be eliminated as suspects, as the old bags could be well bonded and the new bags (not glued) were made of high-quality PE without recyclate.

“We can exclude the usual suspects. Nothing is more deceptive than an obvious fact. What is next on our list? ”

Suspect No. 2: Surface tension

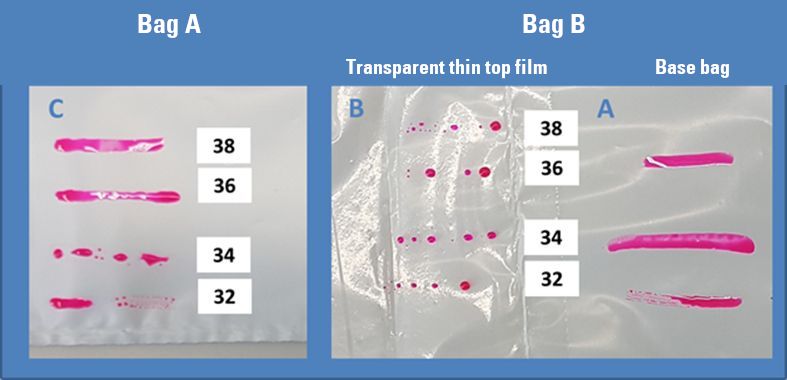

The surface optic of a mailing bag plays an important role as an advertising medium. The two bags are distinguished by an additional thin upper film in the case of the old Bag A. The surface tension of both mailing bags was compared by means of test inks.

As a general rule: the higher the surface tension and thus the value of the test ink (mN/m), the better the wetting. A good wetting is the prerequisite, but no guarantee, for a good bonding (reference value = 36 mN/m or greater).

As can be seen in the figure, the base bag from Bag A has the highest surface tension and the top film of Bag A the worst. The surface tension of the new Bag B lies in the middle. Thus, the wettability of the new bag is generally sufficient for a good bonding.

In this case, the less wettable surface has led to the better bonding strength. As the detectives know, this is due to the adhesive system: The adhesive used is a PSA, a permanently tacky hot melt adhesive, which is ideally suited for bonding of low-energy substrates. All the more mysterious was the failure of the adhesive for our two experts.

“Very strange, this case. The suspects seemed so obviously guilty. Hmmm, who else comes into question? If one rules out all logical solutions to a problem, is the illogical, although impossible, inevitably the right one”.

Suspect. No. 3: Release liner

In general, the bonding of mailing bags by means of pressure-sensitive hot-melt adhesives has proven itself. The use of release liners in the case of mailing bags can reduce the working time to less than 10 seconds per bag. Especially the practical and fast handling of the bags makes them so popular. If it is also fitted with two adhesive strips, the bag can be used by the recipient for returns, if required.

In general, the bonding of mailing bags by means of pressure-sensitive hot-melt adhesives has proven itself. The use of release liners in the case of mailing bags can reduce the working time to less than 10 seconds per bag. Especially the practical and fast handling of the bags makes them so popular. If it is also fitted with two adhesive strips, the bag can be used by the recipient for returns, if required.

Ready for despatch in a few seconds

Both models are equipped with two adhesive closures. Two films of hot melt adhesive are applied to the fold-down flap and each covered with a release liner. The sender of the purchased goods removes the first release liner; the second can be used by the purchaser for a return.

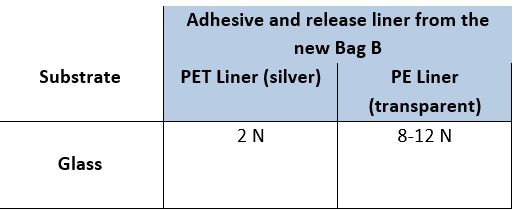

The aim was to compare the adhesive strength of the BÜHNEN adhesive applied to the old mailing bags with the new bags. For this purpose, both adhesive strips from each of the bags were tested on different substrates: In order to obtain a neutral evaluation, they were first applied and tested on glass before testing them on the three film materials of both bags.

The aim was to compare the adhesive strength of the BÜHNEN adhesive applied to the old mailing bags with the new bags. For this purpose, both adhesive strips from each of the bags were tested on different substrates: In order to obtain a neutral evaluation, they were first applied and tested on glass before testing them on the three film materials of both bags.

Different release liners are applied to the two adhesive strips on both films:

- metallised PET- film

- PE

The adhesive strips were always joined to the substrates by rolling once over with the finat test roller. The 180° peel values were determined by means of a pressure load cell directly after the joining.

Result:

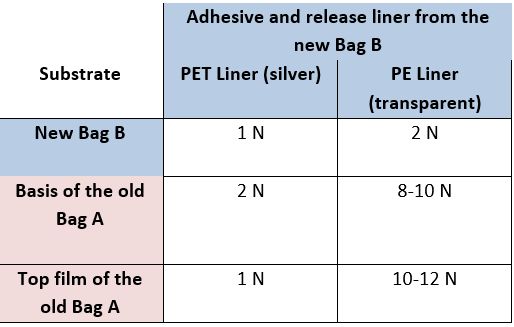

The peel values (in Newton) are summarized in the table.

The gluing on the glass had shown that the silver PET release liner has a negative effect on the bond strength. The metallized PET release liner significantly reduces the bond strength compared to the transparent release liner!

The greatest peel value and thus the best bonding were achieved with the adhesive from the new Bag B (transparent PE release liner) on the basic Bag A. It is also clearly evident that the new mailing bag substrate is much worse than the old mailing bag substrate. Thus the new bag / PE substrate is not suitable for a bonding!

“We have the solution! The intensive investigations have paid off. Let’s inform our customers immediately!”

The offenders could be convicted!

The main problem was the surface properties of the new mailing Bag B compared to the older Bag A. The surface of the new bag could basically not be glued. The reason for this was the nature/production of this new bag.

Another problem was the metalized PET release liner. The silver strip was non-stick-coated, e.g.siliconised. The excess anti-sticking agent contaminated the applied adhesive film. Thus, the bonding deteriorated, as the complete surface was no longer available for adhesion.

It was recommended that the customer switches back to model A. The customer put this recommendation into practice and the recipe of the basic bag was adjusted accordingly. Since the changeover, thousands of bags can again be securely closed and transport the goods safely to the customers.

“Watson Greif and Sherlock Ditze leaned back contentedly against the lab bench. That was a tricky case. It was only possible to prove that the suspect had been responsible for the failure of the bonding after many tests, but the handover of the concluding report to the customer had been worth all the effort. He would recommend the services of the BÜHNEN Detective Agency in the future…”