Pattern control system

A is a trigger programmer for the hot-melt adhesive application. Pattern control systems enable a time or distance–dependent adhesive application. The programming unit is an accessory for melters.

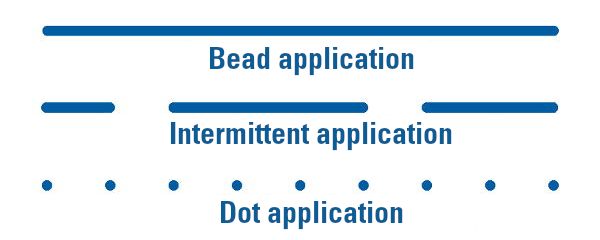

The device is used to programme the type of application (bead or dot application) at variable speeds in order to enable intermittent hot-melt adhesive application.

When the workpiece passes a light sensor at the machine infeed, a time measurement is started in the pattern control system. Depending on the output speed of the workpiece by the parent machine, the pattern control system controls the application of hot-melt adhesive from the melter to the workpiece.

The control is usually programmable on multiple channels. Thus, different programmes for the type and speed of the adhesive application can be imported into the control. These are then called up by the pattern control system as required.

Pattern control systems are used in various automatic applications. They are required in the packaging industry, for example, to enable precise and recurring, intermittent application of adhesive to a cardboard box.

Further areas of application are in the automotive or construction industries