PTC thermistors as temperature sensors in hot glue guns

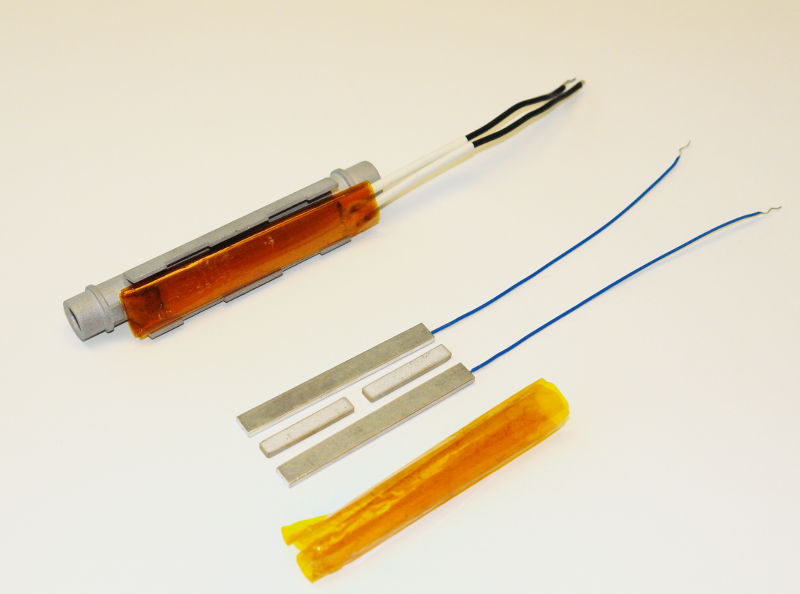

PTC thermistors (Positive Temperature Coefficient) are electrical components that, due to their special physical properties, are often used as temperature sensors in hot glue guns. They consist of semi-conducting materials that exhibit a sudden increase in their electrical resistance as the temperature increases. This property enables precise temperature control and helps to optimise the function and safety of mechanical glue guns.

How a PTC thermistor works

The electrical resistance of a PTC thermistor is not linear:

- At low temperatures, the resistance remains low, so that current can flow virtually unhindered.

- If the temperature reaches a threshold value, (the so-called Curie-temperature), the resistances increases abruptly. This severely limits the flow of current.

This effect acts like a kind of “automatic switch” and protects the device from overheating.

Use of PTC in mechanical glue guns

In hot glue guns, the PTC thermistor is used as a temperature sensor in the heating systems. It performs several important tasks:

- Temperature monitoring

The PTC thermistor measures the current temperature of the hot-melt adhesive. As soon as the optimal operating temperature is reached, it limits the energy supply to the heating element. This prevents the adhesive from overheating, which could affect the quality of the gluing result. - Energy efficiency

By changing the resistance, the PTC thermistor efficiently controls the heating output. This means that less energy is used once the desired temperature is reached. - Safety

If the device overheats due to a defect or improper use, the PTC thermistor protects against damage by reducing or interrupting the flow of current - Life span of the device

Thanks to the precise temperature control, the use of a PTC thermistor helps to extend the life of the hot glue gun and the heating element.

Conclusion

PTC thermistors are indispensable components in mechanical glue guns. They enable precise temperature control, ensure safety and increase energy efficiency. Thanks to their reliable mode of operation, they make a significant contribution to providing users with a consistently high-quality gluing result.