What is the Venturi effect?

The Venturi-Effect describes the physical principal that the flow rate of a gas or liquid increases when it flows through a constriction. At the same time, the pressure decreases.

This principle was named after the Italian physicist Giovanni Battista Venturi (1746–1822), who researched it in the 18th century. Venturi was a prominent hydraulic engineer and recognised that liquids and gases flow faster in a narrowed section of pipe, while the pressure decreases. His work was based on the flow laws of Daniel Bernoulli (1700–1782), a Swiss mathematician and physicist who developed fundamental principles of fluid mechanics.

Application in adhesive conveying

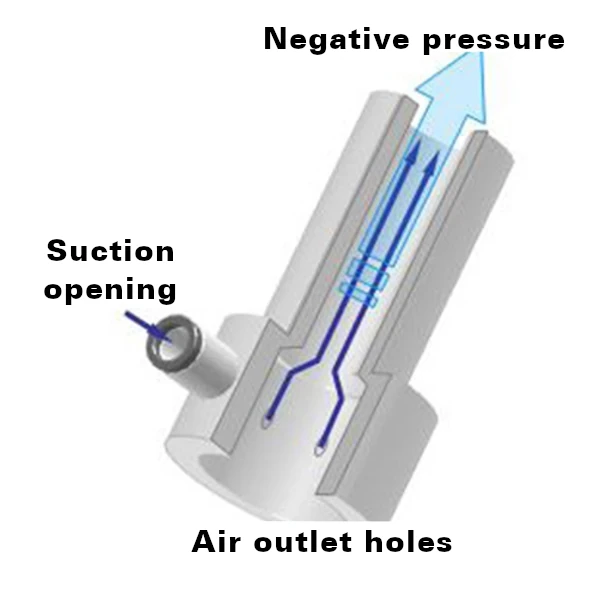

In our granulate conveyor, the Venturi effect is used to transport the adhesive granulate from the granulate container into the melting device:

- Compressed air supply: Compressed air is fed through a narrow nozzle.

- Negative pressure is created: The narrowing increases the air flow speed, while the pressure in this area sinks.

- Granules are sucked in: The resulting negative pressure draws the granules into the air stream.

- Transport to the melting device: The granules are transported through the pipe system into the melting tank.

Thanks to the Venturi effect, the conveying process functions without any moving parts – this makes the system reliable, low-maintenance and energy-efficient.

Ansaugstutzen mit Druckluftrüttler