Wetting

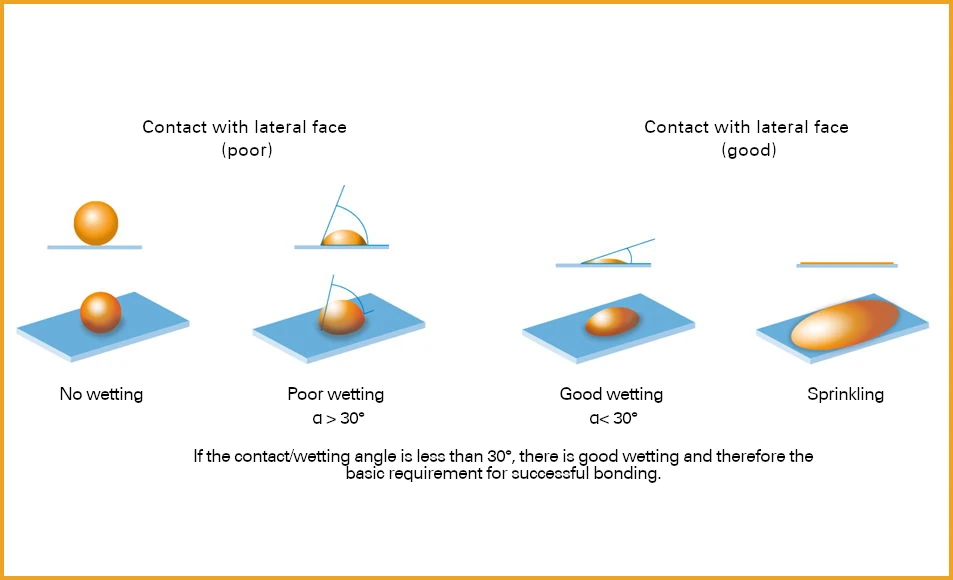

The behaviour of liquids (e.g. hot-melt adhesive) when in contact with the surface of solids.

In order to achieve good wetting of the substrates with a hot-melt adhesive, the surface tension of the adhesive must be lower than that of the parts to be joined.

The adhesive must wet the surface of the substrate well. Wetting of the substrate is a prerequisite for good bonding, in order to build sufficient adhesion between the adhesive and the surface.

Teardrop form with wetting angle

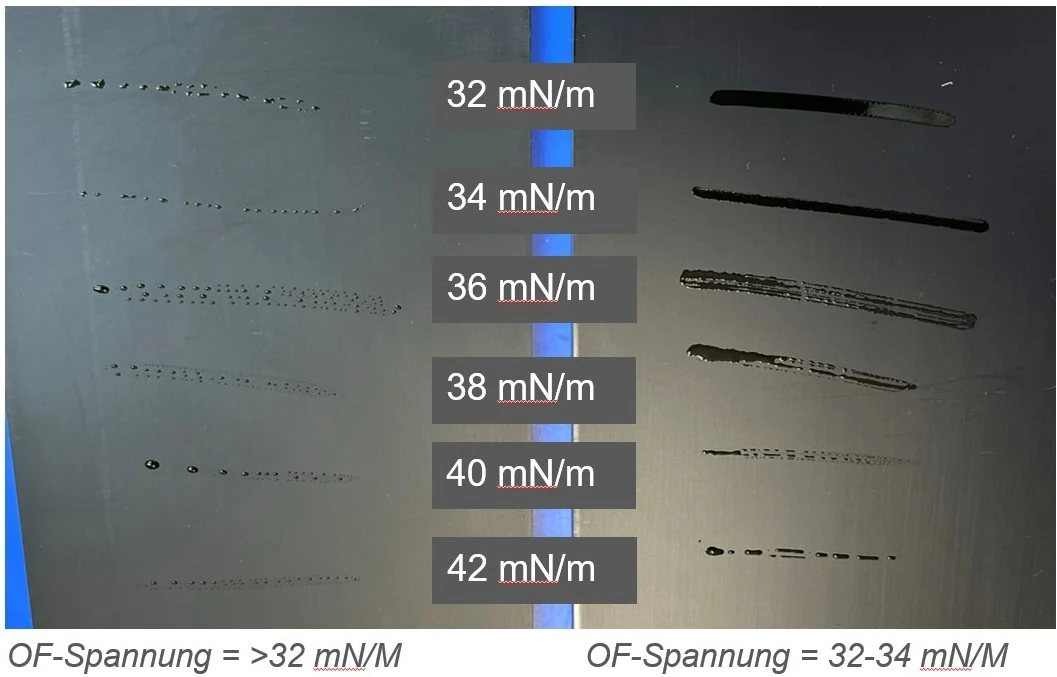

The wettability of a substrate surface can be tested using a test ink. Here, a drop of the test ink (with a defined surface tension) is applied to the surface to be examined.

Measurement of the surface tension by means of test inks (surface only cleaned with isopropanol).

In order to achieve good wetting with a hot-melt adhesive, the surface tension of the parts to be joined must be greater than that of the hot-melt adhesive.

Depending on the surface tension ratio between the test ink and the part to be joined, different teardrop shapes are found, which are characterised by the so-called wetting angle α. The wetting angle α therefore represents a measure of the wetting.

Quelle: IVK, The Art of Gluing, Fig. 7, p. 19

The general rule is: The higher the surface tension of the substrate, the better the wetting.

Good wetting is a prerequisite, but not a guarantee for good adhesion.