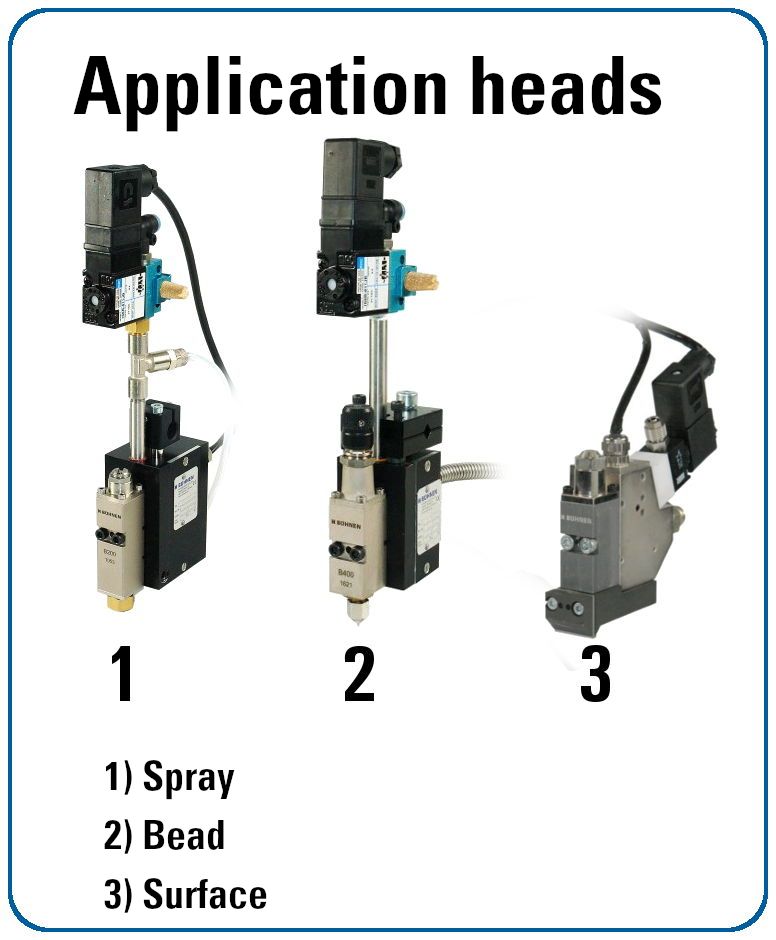

Application head

Application heads are used for automated processes. An application head usually consists of the basic body, a module and a solenoid valve.

Application heads for different applications

If the unit costs are to be reduced in the case of large quantities, the precision of manual application by hand gun is not sufficient, space conditions do not allow manual application or if the adhesive application must be monitored, application heads of different types are used. They are then a component, for example of a packaging machine, and are integrated into the higher-level PLC controller or controlled by a separate line controller. In most cases the application heads are built in and the workpiece is passed through under them.

If the unit costs are to be reduced in the case of large quantities, the precision of manual application by hand gun is not sufficient, space conditions do not allow manual application or if the adhesive application must be monitored, application heads of different types are used. They are then a component, for example of a packaging machine, and are integrated into the higher-level PLC controller or controlled by a separate line controller. In most cases the application heads are built in and the workpiece is passed through under them.

Application heads for bead application

According to their arrangement, beads or dots are applied in a linear form. Depending on the task, one or more application heads are used. In the case of multiple heads, these can be grouped into a block or arranged individually. The hot melt adhesive can then be applied horizontally or, in special cases, inverted.

Application heads for spray application

If workpieces have to be glued together over a large area, spray application heads are used. Spray application heads have advantages even if low adhesive consumption is required. In this case, a thin adhesive strand is laterally deflected by an air vortex, entrained and circularly applied to the workpiece. By a relative movement between the application head and the workpiece, a flat-surface application pattern can be generated. Here, it is not the entire surface that is coated with adhesive, but only lines generated, with points at the intersections of the circles. This type of application is mainly used for the bonding of foam material and paper or cardboard. The applications are limited by the type of adhesive. Depending on the viscosity, open time and flexibility, only certain adhesives can be used.

Application heads for surface application

Surface application heads are a special form of bead application heads. Instead of a nozzle, an adhesive distributor is flanged, which applies the adhesive in the desired width over the entire surface with a very thin layer thickness. While bead or spray application heads always maintain a certain clearance from the workpiece, a surface application head has contact to the substrate. As the substrate grinds on the application head, the lip of the head is not made of brass or aluminium, but of steel and is partially hardened. BÜHNEN surface application heads provide excellent strip-off quality, precise application and are intended for intermittent and continuous application.

Construction of an application head

The basic body has a connection for the hot melt hose and a mounting option on a frame. The basic body also contains the heating with the heating cartridge and the temperature sensor. Bore holes for the guidance of adhesive and compressed air pass through the basic body. Many types additionally include a filter with a fine mesh size.