Cooling behaviour of hot melt adhesives

The working principal of hot melt adhesives consists of a twofold change in the aggregate state: from solid to liquid and back to solid. In the liquid state, the substrates are joined (glued). What happens to the hot melt adhesive during the transition from liquid to solid?

The cooling process

At room temperature, hot melt adhesives are 100% solid. In order that the substrate can be wetted at all, the hot melt adhesive is heated and melted in tank systems. The molten and liquid adhesive is able to wet the surfaces of the substrates. The lower the viscosity of the hot melt adhesive, the better it can adapt to the unevenness of the surfaces and transfer forces after solidification.

The liquid adhesive is conveyed from a heated tank through heated hoses to a heated applicator head. By contact, or also contactless, the hot melt adhesive is applied to the first substrate. After application, the substrates to be bonded must be joined together within the open time, so that the second substrate can be sufficiently wetted by the still liquid adhesive.

By cooling below the solidification temperature, a permanent connection of the substrates is created. The cooling process is relatively fast, so hot melt adhesives generally belong to the adhesives with very short setting times. Exceptions are the PSA adhesives, which do not set.

The setting of the adhesive takes place at different temperatures, depending on the type. The cooling process begins immediately after leaving the nozzle and continues, increasingly, after application to the first adherend.

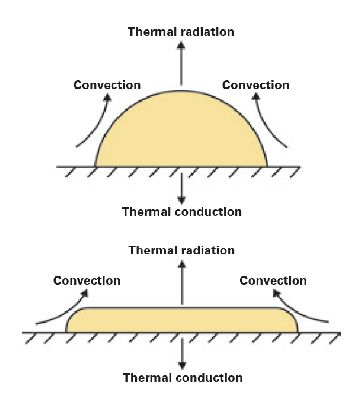

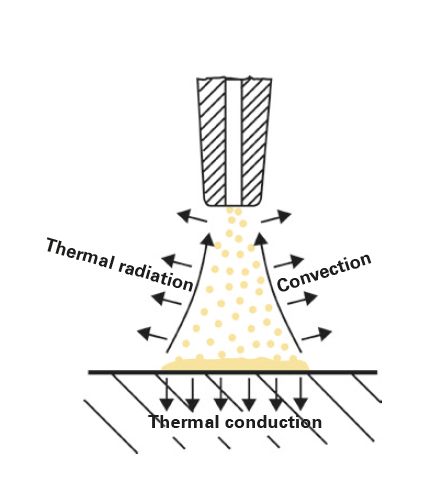

Cooling occurs by

- Heat radiation in the environment

- Heat conduction into the adherends

- Convection (flow of the heat)

Hot melt adhesive applied by the spray method cools faster than adhesive applied in bead application. Basically: the “thicker” the “bead”, the longer the adhesive stays “tacky”.

The cooling behaviour of the adhesive is also influenced by the temperature and the thermal conductivity of the substrate. Preheating the substrates also lengthens or stabilises the open time.

We determine which hot melt adhesive is the suitable one for your production process by tests in our in-house laboratory and careful consultation by your local BÜHNEN employee on-site.