Hot Melt Hoses

The hot melt hoses serve as a heated and flexible transport route for hot melt adhesives from a tank unit to the application head applying the adhesive. They are also used where mobile system parts are to be connected and the supply of hot melt adhesive is to be enabled either with a robot or manually.

Hot melt hoses are made of materials with high temperature stability to ensure a long service life and high operating reliability with precise temperature control. The heating of the hot melt adhesive in the hose guarantees a constant temperature and ensures precise processing.

Construction/ Structure

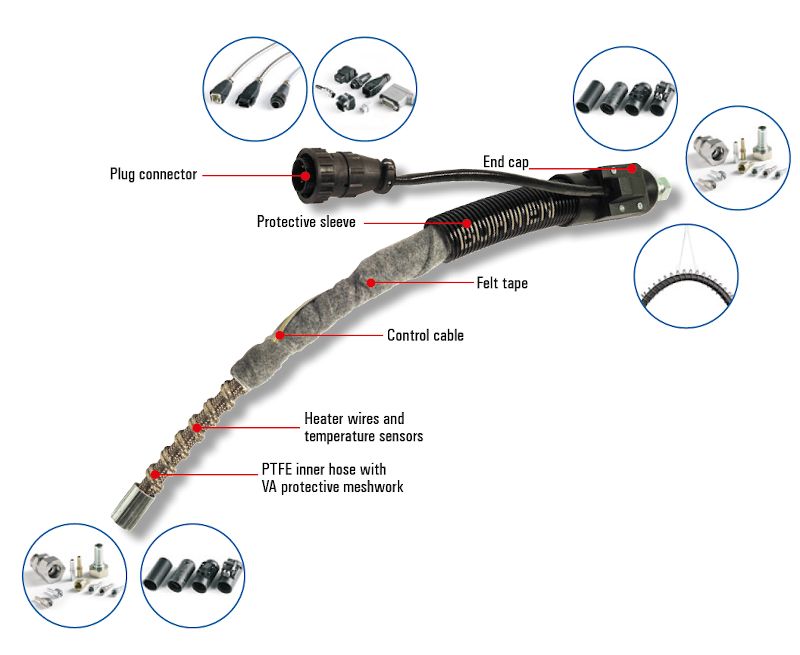

In order to withstand high temperatures, a PTFE inner tube is used for the hot melt hoses. This is encased in a protective jacket of VA mesh braiding, so that it can also withstand correspondingly high pressure.

In order to withstand high temperatures, a PTFE inner tube is used for the hot melt hoses. This is encased in a protective jacket of VA mesh braiding, so that it can also withstand correspondingly high pressure.

The winding insulation of the heating pipeline and the temperature sensor follows in a second layer. Further protection is now ensured by an insulation layer made of heat-resistant felt. This is followed by the control cables and a further insulation made of felt tape.

A thermoplastic elastomer (TPE) corrugated hose serves to protect the thermal insulation. The assembly of the hot melt hoses is completed with end caps, resilient plug connectors and electrical terminals.