Adhesive failure

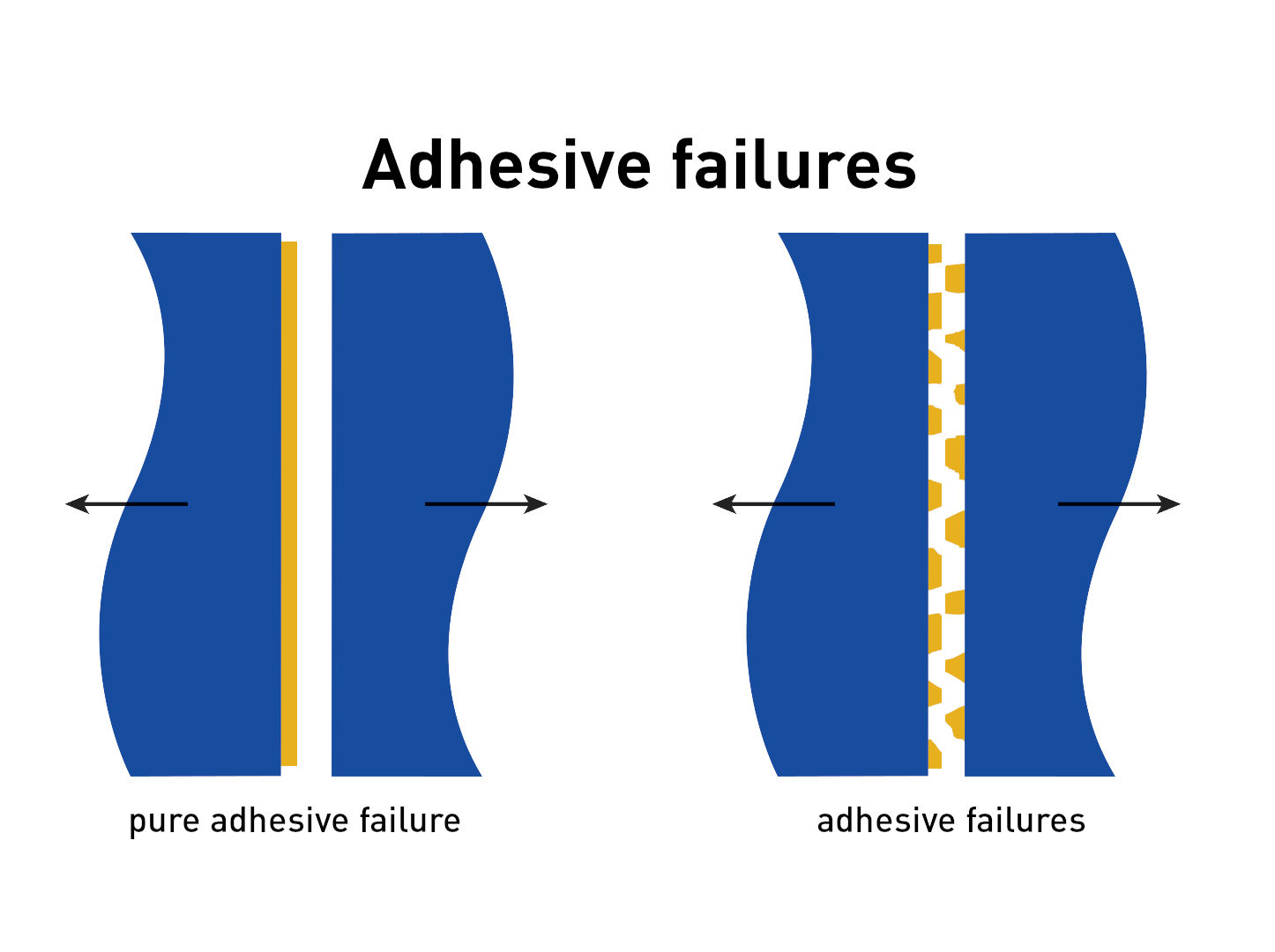

Adhesive and cohesive failures are the two most common forms of failure of an adhesive bond. Adhesive failure occurs when the adhesive completely separates from one of the substrates or separates from both substrates.

If, after testing or failure, the adhesive is completely on one substrate and there is no adhesive at all on the other, this is referred to as pure adhesive failure.

- Pure adhesive failures are usually caused by:

- Unsuitable adhesives: The adhesive is not able to build up adhesion to the substrates in question.

- Surface contamination: Dust, oil, moisture and other contamination on the surface of the part to be bonded can prevent the adhesive from forming a sufficient bond.

Other influencing factors

- Inadequate surface preparation: A poorly prepared surface can significantly affect the adhesion of the adhesive. Surface preparation methods include cleaning, sanding, and chemical pre-treatment.

- Lack of wetting: See surface tension

- Mechanical stress: Constant or sudden stress can weaken the bond of the adhesive to the substrate and lead to adhesive failure.

- Humidity and environmental influences: Prolonged exposure to moisture, extreme temperatures, or chemicals can reduce the adhesive strength.

- Plasticisers in the substrates

Prevention of adhesive failures

- Careful surface preparation: Cleaning and, if necessary, pre-treatment of the surfaces is essential.

- Suitable adhesive selection: Selecting an adhesive that is compatible with the substrate materials and meets the requirements of the application.

By taking these factors into account, adhesive failures can be minimized and the service life and reliability of adhesive bonds can be improved.